ScreeDemon™

When MBW develops a new product, we look for deficiencies in products already in the marketplace. Portable wet screeds suffered 4 serious shortcomings:

Mechanical

Wet screeds were prone to high maintenance, especially in drive mechanisms between the engine and exciter. The ScreeDemon™ employs a simple, durable, low cost rubber isolator to drive the eccentric.

Functional

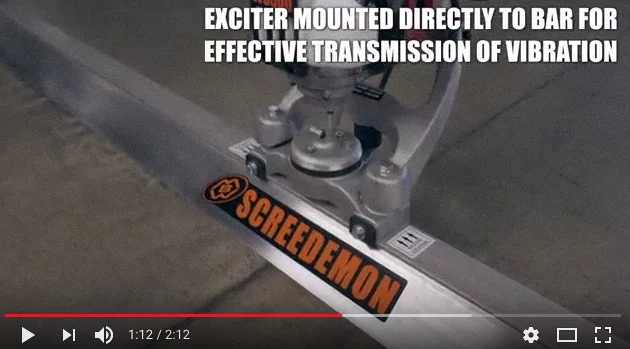

Most screed and screed bar combinations produce irregular vibration along the length of the screed bar. Not only is the concrete exposed to highly variable levels of vibration but cream levels vary from spot to spot along the screed bar. The back-to-back triangular construction of the ScreeDemon™ bar is extremely rigid and minimizes variability in the transmission of vibration.

Most screeds bolt to their screed bars. Hardware threads are compromised by the concrete and assembling or removing the screed becomes such a problem that crews often don’t disassemble for cleaning or transport. The ScreeDemon™ simply clamps to the specially designed bar. No holes to weaken the screed bar. No threads to complicate assembly/disassembly. The ScreeDemon goes together and comes apart in seconds.

Operator Health & Safety

All wet screeds tested by MBW exposed operators to excessive hand/arm vibration. The ScreeDemon’s patented mount retention method enables use of low durometer isolators without loss of operator control. Hand/arm vibration is 50 to 90% lower than competitive screeds.

US & International Patents

| Operating Weight | 29 lb (13.2 kg), 33.5 lb (15.2 kg) |

|---|---|

| Max Rated Power | 1.5 hp (1.12 kW) @7000 rpm |

| Displacement | 2.1 in3 (35 cm3) |

| Fuel Tank Capacity | 0.17 gal (0.64 l) |

| Power Source | Honda GX35, 18V DC Motor Powered by M18 REDLITHIUM |

| M18 REDLITHIUM | With Battery, Without Battery |

Videos

-

ScreeDemon Assembly

-

ScreeDemon™

-

ScreeDemon Bars

-

Pouring A Concrete Slab For A New Garage (30′ x 24′) Form & Pour